Comprehensive Lead Paint Removal Service in NYC-- Certified and Licensed

Comprehensive Lead Paint Removal Service in NYC-- Certified and Licensed

Blog Article

Ideal Practices for Guaranteeing Safe and Extensive Lead Violation Reduction

Attending to lead infraction reduction needs a multi-faceted strategy to make certain both safety and conformity. First analyses utilizing innovative discovery techniques such as XRF analyzers set the phase for an exact understanding of contamination levels. Integrating appropriate containment strategies, including closed obstacles and HEPA purification, paired with the usage of personal protective tools (PPE) for workers, develops the backbone of a safe procedure. Thorough cleanup procedures, including HEPA vacuuming and wet-wiping, are essential. Yet, it's the last clearance procedure, including extensive examinations and research laboratory testing, that absolutely confirms a lead-free environment, making sure lasting safety and security. Exactly how do these methods interconnect to ensure detailed lead reduction?

First Evaluation

Conducting an initial analysis is an important very first step in lead offense abatement. This stage includes a comprehensive assessment of the residential property to determine the visibility, degree, and specific areas of lead-based risks. Certified experts, such as qualified lead examiners or take the chance of assessors, need to do a thorough website inspection, utilizing devices like X-ray fluorescence (XRF) analyzers to accurately spot and determine lead focus in paint, dust, dirt, and water.

The assessment needs to additionally include an evaluation of the building's history, previous reports, and any kind of complaints or wellness concerns reported by passengers - Lead Removal Contractors. Recording the findings diligently is important, as these records create the basis for creating an efficient reduction method. A detailed evaluation likewise includes sampling and laboratory analysis, which are essential to confirm the existence of lead and overview succeeding activities

Furthermore, it is critical to communicate the results transparently to all stakeholders, including homeowner, renters, and regulative authorities. By making sure that the first analysis is performed with precision and rigor, professionals can lay a solid foundation for a targeted and efficient lead abatement process, ultimately protecting public health and wellness and making sure conformity with regulative requirements.

Appropriate Control

Proper control is critical to stop the spread of lead pollutants during reduction activities. Effectively taking care of containment minimizes the threat of lead dust and particles migrating to non-work areas, consequently protecting both the environment and people outside the immediate job zone.

Regular assessments of the containment location are required to examine for breaches or weak points in the barrier. Any kind of determined concerns ought to be immediately resolved to keep the integrity of the control. By adhering to these methods, abatement projects can properly manage lead contamination and minimize involved wellness risks.

Employee Protection

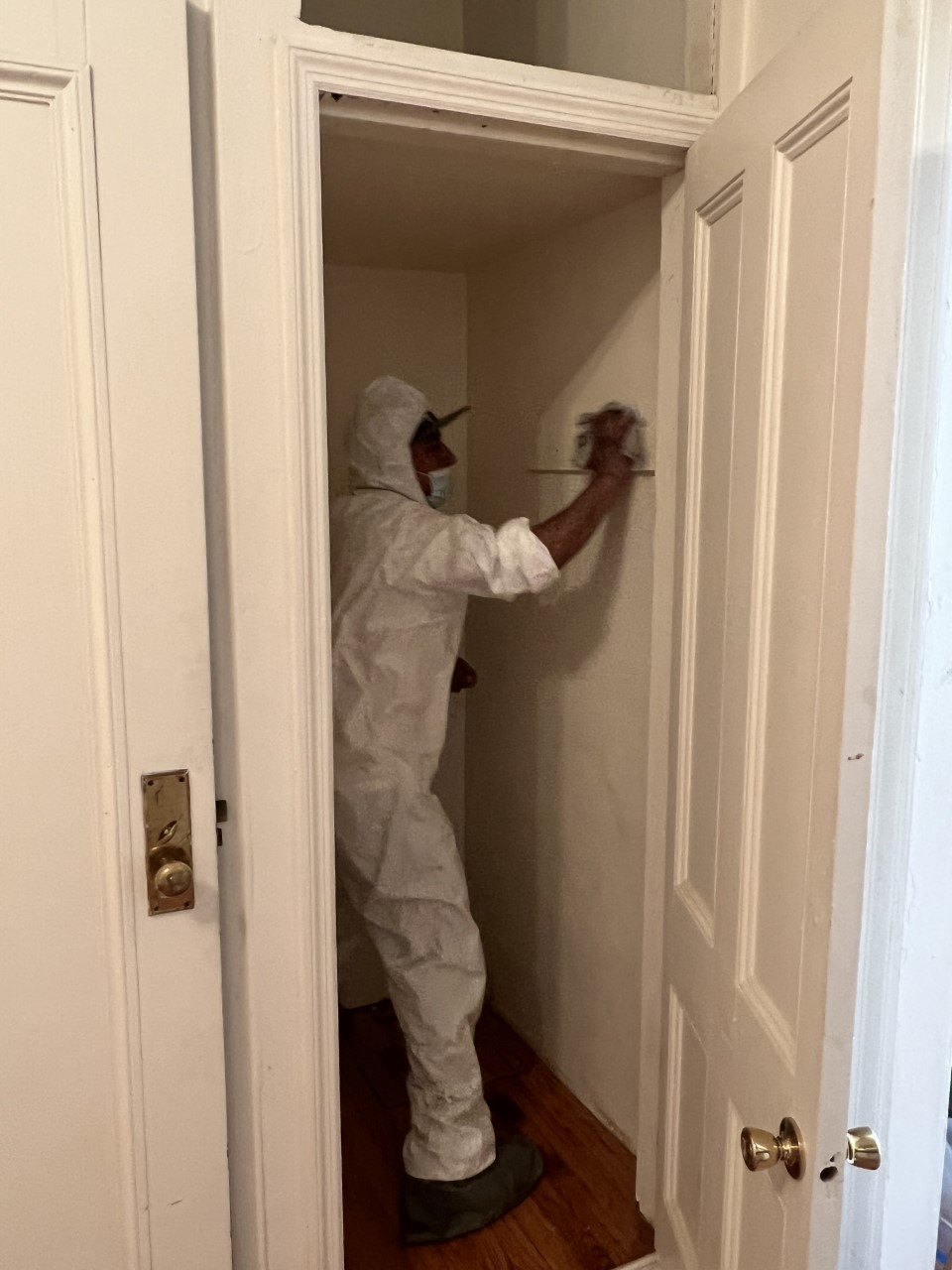

Making sure employee protection is vital during lead abatement tasks to avoid work-related direct exposure to dangerous lead bits. Essential procedures consist of the use of personal safety tools (PPE) such as respirators, gloves, and full-body suits particularly designed to block lead dirt and fumes. Employees should undergo detailed training on the proper usage and maintenance of PPE, including in shape screening for respirators to make certain maximum efficacy.

Engineering controls, such as regional exhaust air flow systems, are critical in minimizing airborne lead concentrations in the work atmosphere. Management controls must additionally be applied, consisting of restricting the period of direct exposure and rotating workers to reduce individual exposure times. Regular medical surveillance and biological monitoring are essential for early detection of lead absorption, enabling timely intervention and therapy.

In addition, developing a purification method is crucial. Employees need to comply with strict decontamination procedures before breaks and at the end of their change to avoid lead dirt from being brought outside the workspace. This includes comprehensive hand and face washing with lead-specific cleaner and altering out of contaminated clothing.

Meticulous Cleaning

Preserving a risk-free work setting expands beyond worker defense and incorporates precise cleanup to ensure lead fragments are completely removed from the website. The procedure of precise cleanup is essential in protecting against the recontamination of the mellowed out area and guarding both present and future residents.

To achieve a thorough clean-up, all job areas must be methodically decontaminated. This entails making use of specialized HEPA (High-Efficiency Particulate Air) vacuum and wet-wiping strategies to catch and get rid of fine lead dirt that may have resolved on surfaces. It is important to cleanse all horizontal surface areas, including floors, home window sills, and counter tops, along with my link vertical surface areas that may have caught lead fragments.

Workers have to wear ideal personal safety equipment (PPE) during cleaning to avoid exposure to recurring lead dust. Utilized cleansing materials such as wipes, sponges, and wipe heads need to be gotten rid of based on contaminated materials disposal regulations.

Final Clearance

Final clearance is the essential wrapping up phase of lead abatement that figures out whether the website is risk-free for reoccupation. This important action entails thorough examination and screening website link to validate that all lead threats have actually been properly removed.

Last clearance screening not only protects future owners yet likewise guarantees compliance with neighborhood, state, and government policies. It serves as a recorded validation of the reduction specialist's adherence to industry ideal methods. Guaranteeing a thorough and effective final clearance is crucial in securing public health and cultivating rely on the reduction process.

Verdict

Guaranteeing safe and complete lead violation reduction necessitates a diverse approach including initial evaluations with advanced detection approaches, effective control techniques, rigid worker security methods, and precise cleaning procedures. The final clearance stage, featuring comprehensive examinations and laboratory screening, is crucial to verify conformity with EPA criteria. Adherence to these best methods assures a safe environment for passengers, minimizes health dangers, and promotes regulatory demands, therefore advertising public health and safety in lead-affected areas.

Report this page